Orange Cat Packs uses a variety of high performance fabrics in the construction of our bags. Keep scrolling to learn more about the different materials and to see swatches of your many colour options for designing your own custom bags.

There is an incredible spectrum of technical outdoor fabrics out there to choose from when designing bags. From lightweight ripstop, to burly canvas, and more recently a growing range of laminate fabrics that have been developed with technologies from high performance sail manufacturers.

Each style of fabric has its own unique pros and cons and no one fabric can be held up as "the best" for all applications.

We've done lots of testing and experimenting and we think we've found the best options for each part of our bags. Anytime you're offered a selection of colours and materials to choose from you can be confident that any of the options you're given will make for a great final product.

A quick note on "waterproofness"...

Many technical fabrics are described and marketed as "waterproof" but within that category you will find a wide range of actual performance.

More importantly though, the minute two pieces of "waterproof" fabric are joined with a needle and thread, that seam introduces a potential route for water to creap in. There are techniques and materials that can seal that stitched seam and preserve the waterproof barrier, but this introduces a number of restrictions on the shape and design of a bag, as well as limiting the types of fabrics that can be used.

When it comes to bike bags, the majority of designs and shapes simply cannot be fully seam sealed without sacrificing a large portion of the functionality of the bag. We design our bags to be as water resistant as possible while preserving excellent form and function. Where it's appropriate we may use seam tapes to seal a critical seam or a point that would be particularly prone to water ingress, but we can't in good faith claim that any of our finished products are "waterproof".

Swatches and fabric styles

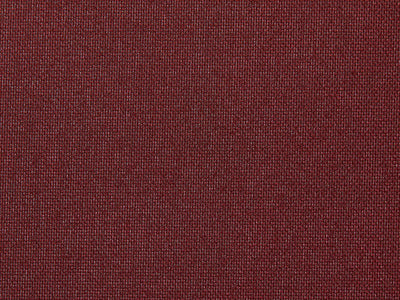

Cordura

These durable woven synthetics are made from either nylon or

polyester and are a long time staple of the outdoor industry. It comes in a range of weights and finishes and is highly abrasion resistant. Cordura is also available in a large number of colours

and prints, but it is relatively heavy and although treated, it is only

water resistant.

Cordura fabrics are used for

the trim section of frame bags and top tube bags where its ability to stretch and handle curves is most valuable and its high durability will hold up to the repeated wear and abrasion from the bike frame and fittings. Cordura can also be used on

other smaller bags to show off its awesome colours and patterns. Because of its

weight and softer hand it isn't well suited to large flat panels that

need to hold their own shape.

Solid colours are 1000d Nylon, prints are either 1000d Polyester (marked HP) or 500d Nylon. Polyester printed fabrics may be more prone to fading over time from UV exposure.

Ecopak Overview

Ecopak is part of a new generation of outdoor fabrics that grew out of technologies used in high performance sailcloth. These fabrics are "laminates" that are made by bonding multiple layers of fabric and film into one final material. There is a huge range of different styles within this laminate category but in general laminates are lighter, stiffer and less stretchy (hold their shape better), and more waterproof than a tradition woven fabric with similar durability.

Ecopak covers a range of laminate fabrics developed by Challenge Sailcloth using largely recycled polyester fabrics and films (instead of virgin nylon) and a less resource intensive manufacturing process than most previous laminate options. It was the first significant release of recycled laminates and remains the broadest range of recycled colours and fabric styles.

Ecopak comes in two main categories, EPX and EPLX.

EPX laminates have three layers, a fabric outer, a stabilizing cross ply, and a fabric backing layer. These fabrics are light and supple and make for excellent thin and light bags. The fabric backing give thin and light single layer bags a bright interior and protects the fabric from abrasion and damage from whatever you throw in them. The adhesive that bonds these layers together forms a waterproof barrier and gives these fabrics a truely "waterproof" rating in lab testing. In our testing however, we've found seams in these EPX fabrics to be slightly more prone to wetting out than other laminates.

EPLX laminates have a different three layer construction, with a fabric outer, a stabilizing cross ply, and a film backing layer. This film backing provides a more substantial waterproof barrier and in some cases allows stitching that might compromise that waterproofness to be "taped" and sealed. For the most water resistant finished bag consider choosing EPLX fabrics. EPLX is stiffer and more prone to creasing and crumpling vs EPX and the film backing is less suited to thin and light single layer bags that would leave that backing exposed.

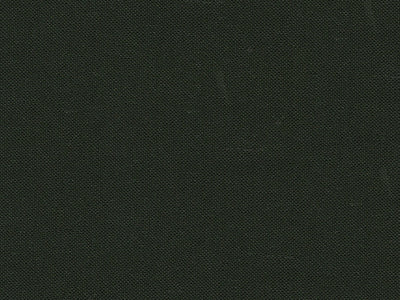

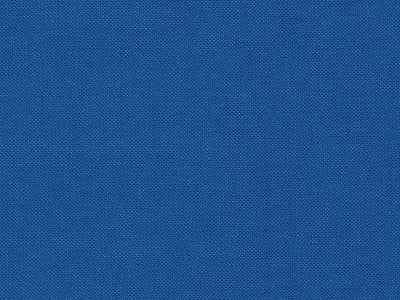

Ecopak EPLX400

Ecopak EPLX400 is a light and durable film backed laminate, perfect for

the side panels of frame bags. The colour range is more limited but this

fabric significantly outperforms EPX200 in terms of durability and

waterproofness and is only marginally heavier. EPLX is stiffer and more

prone to creasing and crinkling so it isn't as well suited to small

complex shapes like our roll top saddle bags.

Weight: 7.2 oz/yd² , 244 gsm

Abrasion - ATSM 3884: 3000 Cycles

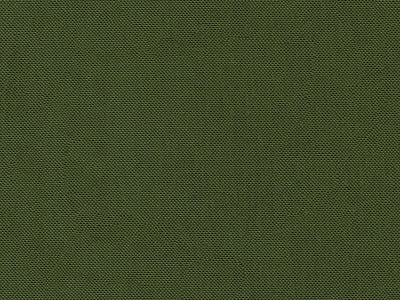

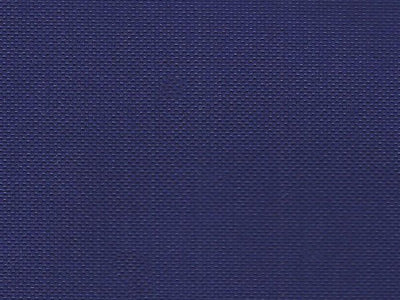

Ecopak EPX200

EPX200 is a light weight fabric backed laminate that's available in the

widest range of colours. It is perfect for adding colour accents to

larger bags and for making smaller, lighter bags that aren't expected to

take quite as much abuse as a frame bag.

Weight: 6.4 oz/yd² , 216 gsm

Abrasion - ATSM 3884: 500 Cycles

Ecopak Extras

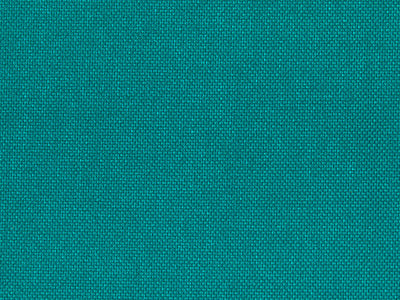

EPX70HH - Dark Heather

This unique fabric backed laminate is the thinnest and lightest of our options but has an impressive abrasion resistance due to a proprietary liquid crystal surface treatment. That surface finish also seems to improve the fabric's ability to shed water vs more traditional DWR treatments. It's best suited to smaller bags and we primarily use it in our roll top saddle bags.

Weight: 5.25 oz/yd² , 178 gsm

Abrasion - ATSM 3884: 1000 Cycles

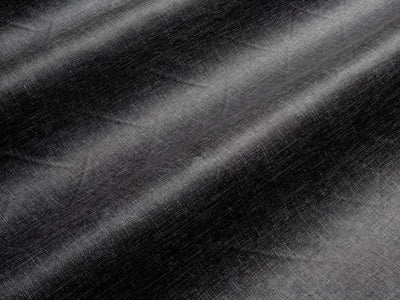

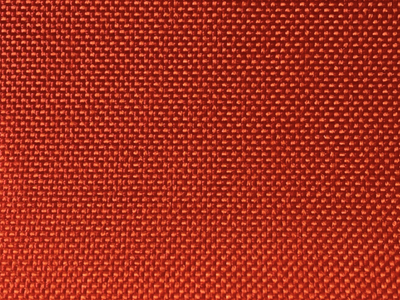

EPX300RS - Black

Significantly more durable than EPX200 but keeping the same nice soft hand feel, this laminate has a 300d ripstop face and a fabric backing. If you like the ripstop finish this can be a great option for most bags.

Weight: 8.8 oz/yd² , 298 gsm

Abrasion - ATSM 3884: 1000 Cycles

EPLX600 - Dark Multicam

Combining the performance of EPLX with the iconic Multicam pattern, this laminate makes for super bomber bags. The heavier 600d face fabric is quite stiff and adds a lot of structure to bags. That does make it a little too stiff for hip packs and saddle bags though.

Weight: 8.85 oz/yd² , 300 gsm

Abrasion - ATSM 3884: 2000 Cycles

Ultra200TX - Black

Ultra fabrics are at the cutting edge of technical outdoor gear. They offer incredible toughness in an ultralight material thanks to the woven UHMWPE face fabric. The TX variant combines that face fabric with the best elements of EPLX and EPX to make arguably the best possible fabric for bike bags.

Ultra carries a significant price premium but makes for absolutely incredible lightweight bags.

Weight: 5.9 oz/yd² , 200 gsm

Abrasion - ATSM 3884: 4400 Cycles